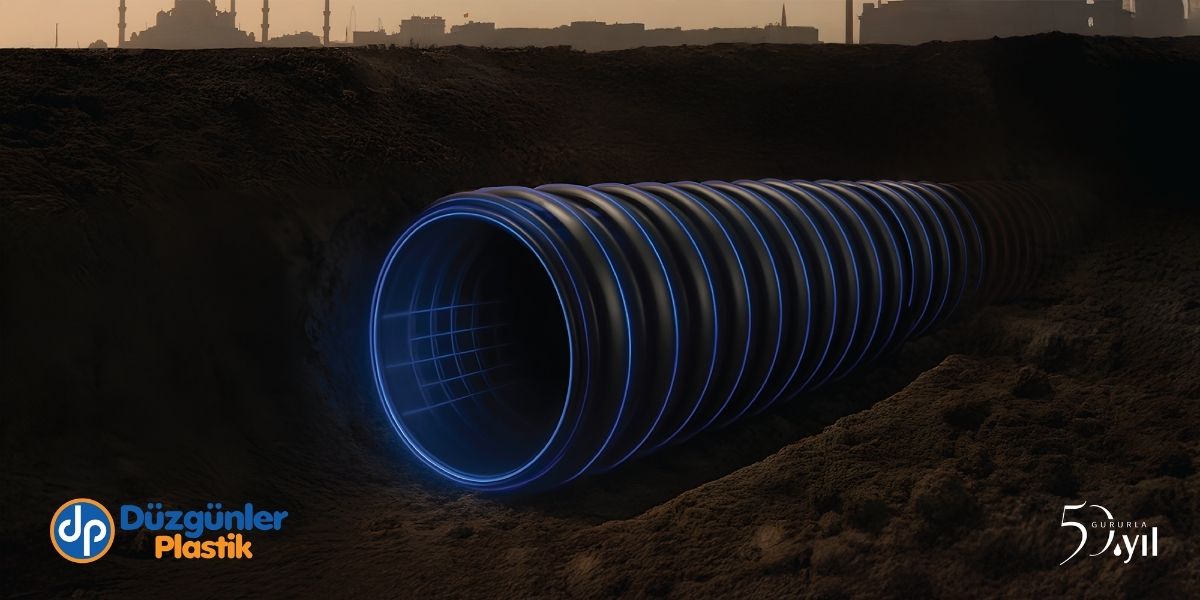

Corrugated pipes are manufactured from HDPE with a ribbed outer wall and a smooth inner surface. The geometry provides high ring stiffness against soil loads while maintaining low friction for internal flow. The result is a lightweight, durable, chemically resistant and long-lasting pipeline solution. Düzgünler Plastik’s Triplex production technology optimizes multi-layer mechanics for impact and ground-movement resistance.

Domestic and industrial wastewater networks

Rainwater drainage systems

Culverts and storm channels

Cable protection and utility crossings

Agricultural drainage and field water management

In all these use cases, chemical resistance, flexibility and sealing performance directly affect lifecycle cost and operational reliability.

Düzgünler Plastik supplies SN4 and SN8 class corrugated pipes. SN denotes ring stiffness against external loads.

SN4: Suitable for standard backfill heights and non-heavy traffic conditions.

SN8: Preferred for higher traffic loads, greater cover heights or areas with pronounced soil movement.

Selecting the proper SN class based on loading, compaction and cover depth is essential for service life.

High chemical resistance: Suitable for aggressive wastewater environments.

Flexibility: Tolerates settlements and minor displacements, reducing break risk.

Lightweight: Cuts transport and installation costs and speeds up site work.

Low roughness: Smooth inner wall preserves hydraulic efficiency at high flows.

Leak-tight joints: Sealing-ring socket design minimizes exfiltration and infiltration.

Düzgünler Plastik corrugated pipes use gasketed socket joints for fast, reliable installation. Proper cleaning, lubrication and axial alignment secure the watertight connection, protecting groundwater and sustaining hydraulic performance across the network.

Triplex technology calibrates a multi-layer HDPE body for targeted performance: an outer layer for impact and ring-load resistance, and an inner layer for flow efficiency and abrasion resistance. The synergy helps SN4/SN8 classes deliver consistent field performance.

Founded in 1975 by Ekrem Düzgün, Düzgünler Plastik has scaled into a modern manufacturing campus with 100,000 m² open and 30,000 m² closed area in Konya. From agricultural tools to automotive components, the company’s industrial breadth now anchors high-reliability products such as HDPE corrugated pipes and submersible pump plastic column pipes, backed by innovative R&D, quality assurance and a customer-centric service model.

Flow and slope: Size the internal diameter via hydraulic calculation.

Cover and traffic: Choose SN4 or SN8 based on soil cover and live loads.

Soil conditions: Consider settlements, frost and groundwater table.

Joint detail: Verify spigot-socket fit and gasket compatibility.

Maintenance plan: Ensure cleaning equipment compatibility and access points.

Düzgünler Plastik corrugated pipes provide a reliable, economical and long-life infrastructure option by combining HDPE material advantages, SN4–SN8 ring stiffness classes, leak-tight gasketed joints and Triplex technology.

For more information about our products and production processes, please contact us.

For more content, please visit our blog.